Flat Pack Container House for Prefabricated Modular Mining Camp

Basic Info.

| Installation | Install on Site, Fast and Easy |

| Connection | All by Bolt |

| Insulation | EPS, PU, Rock Wool |

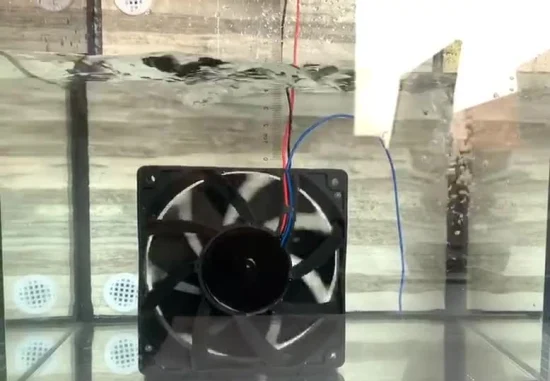

| Electricity | Light, Switch, Socket, Distribution Box, Breaker |

| Size | 6058*2438*2591mm |

| Transport Package | 7units/40′hq or 4units/20′soc |

| Specification | CE; ISO9001: 2008 |

| Trademark | PTH |

| Origin | Shaoxing, Zhejiang China |

| HS Code | 9406000090 |

| Production Capacity | 500 Sets/Month |

Product Description

Flat Pack Container House for Prefabricated Modular Mining Camp

Detailed Photos

Product Description

Specifications

| Size | Length | 6058mm / 6000mm or customized | |

| Width | 2438mm /3000mm or customized | ||

| Height | 2600mm / 2791mm / 3000mm or customized | ||

| Clear height indoor | 5800mm*2200mm*2300mm, it is changable | ||

Standard accessory | Roof System | Top structure + 70mm thick integrated PU foam insulation + embedded electrical system | |

Chassis System | steel struction chassis + 18mm thickness cement-fiber board + 2mm thickness PVC floor sheet (glass wool insulation for optional) | ||

Permitted loading:>2.5KN/m2 | |||

Wall System | 50/75/100mm EPS sandwich panel, rock wool sandwich panel,glass fiber sandwich panel, or PU sandwich panel | ||

Door System | Steel door / Fire-proof door / Sandwich panel door | ||

Window System | Aluminum alloy shutter window and the plastic-steel window, single or double glass | ||

Floor System | PVC, plywood or customized | ||

Option | Drainage system | Provided plan, design and constrution | |

Electric system | Provided plan, design and constrution | ||

Technical parameter | Resistant temperature | -40ºC to 40ºC | |

Wind resistance | 210km/h | ||

Earthquake resistance | Grade 8 | ||

PTH flat-pack container house type

Process Characteristics

Packaging & Shipping

Other Product Recommendations

PTH Other product recommendations

| CONTAINER HOUSE | DOUBLE-C STRUCTURE |

LIGHT GAUGE STEEL | STEEL STRUCTURE BUILDING |

Company Profile

FAQ

1. Do you provide on-site installation service?

We provide very detailed installation instrution drawings and videos for every project. For large projects, we will have both installation workers and supervisiors on site. The fee for the on-site service should be negotiated with clients.

2.What's your delivery time?

Normally, delivery time is 15 days after deposit received. For large order, the delivery time should be negotiated.

3.How to control the quality of your product?

a. quality of the design: think about possible problems in advance and provide a high-quality design solution.

b. quality of the raw material: choose the qualified raw material

c. quality of the production:precise manufacturing technique, experienced workers, strict quality inspection.

4. How to deal with quality problems?

Warranty is 2 years. Within the warranty period, PTH will responsible for all quality problems caused by our production.

5. If there is a clear service life of your products? If have, how long?

Under conventional climate and environment, the service life of container house steel frame is 20 years

6. What designs do you have in different climates (How can the products adopt to different climates)?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anticorrosive coating.